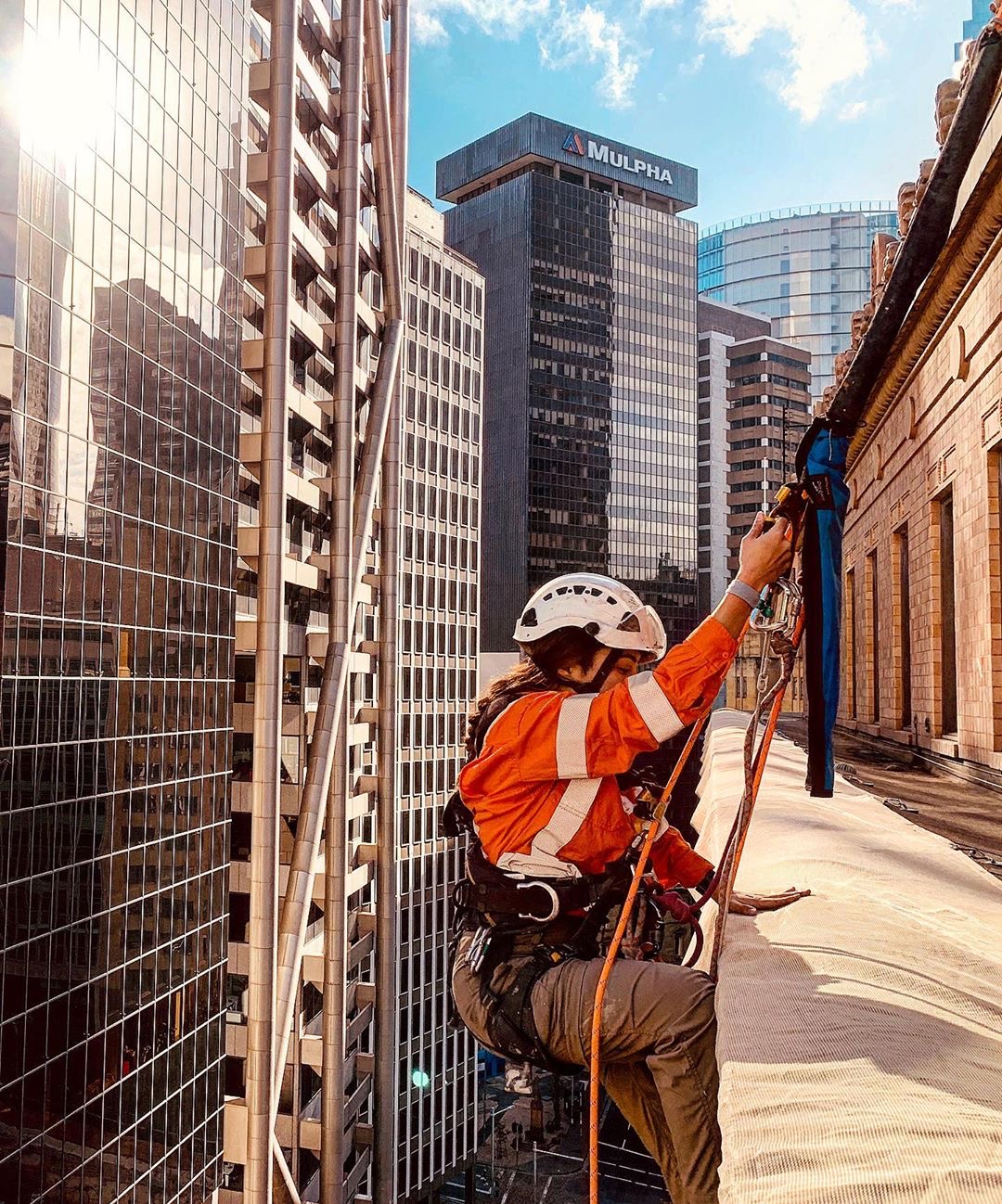

SAFETY NET INSTALLATION

Industries across all sectors are obliged to follow Occupational Health and Safety (OHS) regulations of their states and territories to ensure the safety of their employees. Many clients today are realising that poor rigging practices of fall arrest safety nets can lead to increased risk and injury.

At JG Vertical, our rope access experts ensure all safety nets are installed following the standards and guidelines in Australia (BS EN 1263-1, 1263-2 (2002), ASNZ4576, ISO9001:2008). This involves a performance based approach to test the integrity of a safety net when working at great heights.

With JG Vertical, you get:

- Nets installed by competent and trained personnel

- A practicable solution when working at heights

- Improved safety compliance and preventative measures

- Effective as physical barriers at midpoints of falls

- Used as Primary or Secondary arrest system

- A net inspection check point system after installation

- Extremely economical compared to other systems

- Nets can be used again

How do safety nets work?

Fall arrest safety netting works by absorbing energy created during a fall. The intertwined meshes are released slowly through the net’s cords system. Therefore, having the correct fall height and sag is a critical part of construction safety net installation for safety systems to adhere to safe work conditions.

Importance of construction safety net installation

Ensuring site health, safety standards and keeping your employees safe reduces the risk of increased site overheads via work stoppages and loss of staff. Whatever the size of your construction project whether it’s a large commercial site to a new residential home build, the safety of your employees is the number one consideration. When installed and assessed by professionals, the fall arrest system has many benefits. Aside from delivering a low cost (reuse), it can be used as part of your safety solutions when working at great heights. Other safety benefits of safety net installation:

- Reduces potential falls and minimise incident effects

- Provides collective passive safety

- Provides worker reassurance by fitting the fall nets as close as possible to working level

- Allow a broader range of activity to continue working with minimum restriction

- Permits greater mobility for personnel working above nets

- Reduce crane times and costs

- Can be used in conjunction with scaffolding

- Reduces costs compared to other fall protection systems

Who Can Install Safety Nets and Inspect Installation?

JG Vertical’s team of rope access experts are trained in all aspects of safety net installation. From ensuring that the knots on your net are secure, regularly inspecting for damage in the mesh and inspection tags to ensuring tie spacing is less than 2.5m and at recommended intervals @1.5m -2.0m, JG Vertical has you covered.

Our experienced team can assist you with installation and testing designed to meet OHS legislative requirements. This can include assistance in site specific safety net design, planning needs, fall prevention risk assessment as well as project work at height plans. As part of our comprehensive services, we can provide net installation where required, deliver the required inspection and testing certification on site, and ongoing net maintenance to ensure you get the most out of your safety systems.

Meanwhile, our team of net inspectors can validate net installation in accordance with compliance documentations.

Contact us for a free quote today

GET IN TOUCH

Find out how we can meet your safety net installation needs today.

JG vertical provides a comprehensive range of building maintenance, cleaning and safety services. See how we can go further to fulfil your needs today. With an industry leading safety record we follow Australian safety regulations to always operate with safety in mind.

Safety is a top priority for the JG Vertical team. For this reason our team is trained and certified according to the official Australian safety regulations.